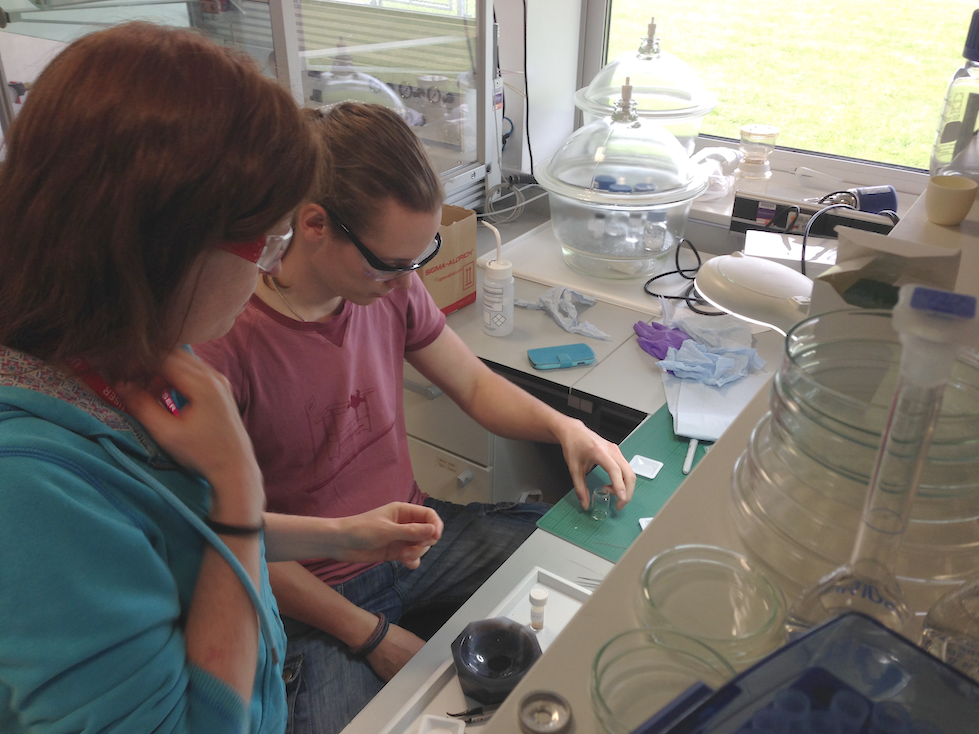

Zoë Schnepp wrote a recent paper, based on the experiments we did at Diamond (these ones). These experiments revealed some amazing XRD data, giving insight on how oxides and nitrides are formed during the (sol-gel) synthesis of iron carbide.

The experiment ran quite well, despite the finicky reaction cell and gas set-up used to flow a little inert atmosphere through the reaction mixture. The team worked well resulting in a mostly stress-free couple of days, though many hours of sleep were (voluntarily) donated by Zoë and Martin.

The experiment is closely linked to the previous work, where catalytic material was synthesized by heating of a carbon-rich compound with dispersed metal salts. The previous experiments showed that under inert conditions, metal carbides and -nitrides can form, existing as nanoscale crystals dispersed through the material. However, the mechanism through which they are formed was not clear.

One method for discovering the synthetic pathway is to synthesize the material as usual, but to interrupt the reaction (by cooling down the oven and material before the conversion is complete). While such experiments may offer some insight, the cooling (“quenching”) is far from instantaneous. This can result in the thermal equilibration of metastable intermediates to other materials, obscuring the sought after intermediaries.

Performing the synthesis in-situ is a good symbiotic technique to the aforementioned ex-situ methods, and can offer supporting and clarifying information. The downside to in-situ experiments is that typically only one or two “probing” methods (diffraction, scattering) can be done simultaneously, and the intermediate material is not available for subsequent analysis. Furthermore, in-situ sample cells can form a quite different reaction environment than that in which the ex-situ synthesis is performed. These differences can be significant, and so such experiments need to be performed whilst keeping in mind that they may not reflect the ex-situ synthesis pathway.

In the current experiment, the chosen probing technique was high-resolution X-ray diffraction (HRXRD), and the reaction the formation of iron nitride and carbide from an iron oxide sol-gel precursor based on gelatin. The results indicate that the mechanism to form the iron carbide passes through an iron nitride stage, confirming similar mechanistic suspicions from the previous ex-situ investigations. In addition to the mechanistic information, some information on crystallite size could also be inferred, from which it is evident that some of the intermediate stages contain crystallites of much smaller size than what was expected, hinting towards large changes in size as the reaction proceeds.

In short, the results offer useful information on how the reaction proceeds, which may be used to tune particular stages of the reaction. The deviation in reaction environment from this small in-situ reactor to the larger-scale laboratory furnace reactions, however, prevents a 1:1 translation of conditions. To fully use these in-situ reaction results for ex-situ reactions, detailed links between these may need to be established.

Leave a Reply