A while ago, we had a meeting in our lab to evaluate the current state of the USAXS instrument, and whether it needs modifications. We decided to move away from the pneumatics…

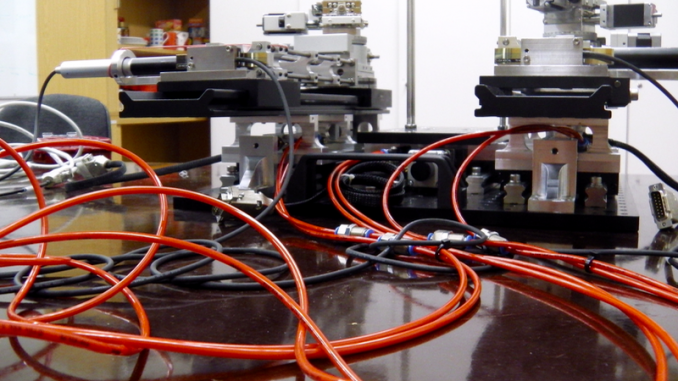

The pneumatics were introduced to allow a fast switch between USAXS and normal SAXS modes. The idea was that a switch between modes would take mere seconds. The end positions were to be controlled using motorized linear actuators resting against the end stops.

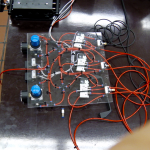

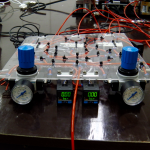

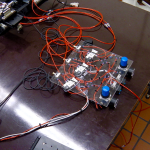

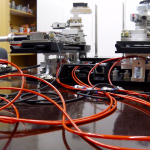

This short video shows you how that moves with a few bar pressure from the control board. The control board allows the setting of the pressure for the three pistons (and for the pilot valve), and has needle valves for controlling the flow speed. However, as evident from the video, the central stage does not move smoothly, and the two towers, which have a considerable weight, ram into their end stops with quite a bit of force. This is probably not a good idea.

Therefore, to be on the cautious side, we’ve decided to switch to linear stages for the three motorized movements instead. We know those can move surprisingly fast with the right stepper motor controller. In comparison to pneumatics, the stepper motor controller, however, gently accelerates and decelerates the stages near the end points.

I’m a bit sad to see the pneumatic bases go, since there was quite some work involved in their design, and I was quite proud of how they turned out. I do agree it’s the sensible choice at this point, as it will simplify control of the instrument greatly as well. It also makes the entire central section of the electrical system redundant.

So this post is the final huzza for the pneumatics before they go. Enjoy the video and the pictures!

Leave a Reply