The BAM workshop came back to me with the 18 requested workpieces. Assembly went smooth until it hit a snag..Having used openSCAD to do most of the piece design and fittings, I was happy to find that all pieces fit very well. Although since it is hard to judge scale in a 3D drawing program, it appears I overengineered the screw connections a bit as there are at least twice as many screw connection points than necessary.

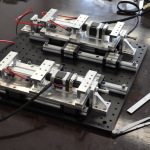

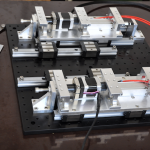

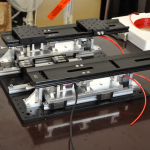

The gallery shows three views of the current state of the instrument design. These shuttles should move back and forth a little, and contain a piston and a motorized end stop (where I really hope the motorized end stops can handle the repeated (mild) impacts.

However, this was followed by the following experience from my side:

It is not a big issue, but one of the drawings didn’t have an offset clearly drawn. That meant that the mount for the motorized actuator is 1 mm too high, which interferes with the rest of the design. So I now have a bit of an apology to make to the workshop, and I’ll have to ask them to make the two offending pieces again. It may not seem like a big issue from the outside, but for me this blunder has hurt. Anyway, time to get over it, fix it, and get on with designing the next parts.

Thanks to Patrick Saloga for taking the second series of images!

Leave a Reply