Looking through the basements of the institute I work at is a favourite pastime of mine. This way, I have found many interesting things to play with, and (dark-)rooms to use. Recently, we picked up a laser engraver from there. Here’s what it can do.

The laser engraver is a relatively modern Epilog engraver. This one contains a 30W CO2 laser, a large bed for the material to sit on, and a massive filtration system underneath. It had been bought for a previous project of a now-retired researcher, and abandoned since then.

According to the documents, it can engrave leather, paper, wood, plastic and anodized aluminium, and cut through paper, leather, wood and plastic. We brought the laser up to our development lab, and started playing with it. The thing pretends to be a printer, so you can easily print anything you draw, with a resolution up to 500 dpi.

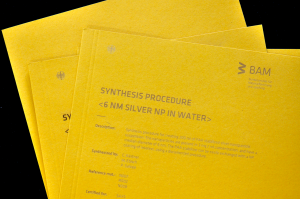

Engraving works fine, and we can nicely emboss images onto leather notebooks, and text onto folders (Figure 2). Setting the laser power too high will cause the parts to be cut clean off, so one should be careful.

But the real interest is in cutting materials. For the 3D printer, making large, flat objects can be a bit of a challenge (warping is an issue), it is time consuming, and uses large amounts of material. It would be better if those things can be taken over by the engraver. Testing it on 3mm acrylic sheets turned out to be no problem, once you figure out how to get the laser to cut vectors, and we made some base plates for mounting printed circuit boards and connectors on. Legend has it that this thing can cut through much thicker materials as well, so we’ll continue our tests. The only thing it shouldn’t cut is PVC (and vinyl and so on), as that decomposes to noxious and corrosive gases when blasted.

And, before I get questions from the workshop: yes, this is something the workshop could do too. However, when I only need one flat bit to prop up a doodad, this will do for starters.

So, check out the funny examples on the Epilog site, including engraving of cookies and pies, and head to your own basements for exploration and discovery!

Leave a Reply