The first major breakdown of the MOUSE happened about 1.5 months ago: our nice X-ray detector blew another fuse, and this time we somehow broke the fuse holder when trying to extract it. Not a big breakdown, but still something that necessitated a trip to the manufacturer, and led to the first long downtime of our high-throughput instrument. An ideal time, then, to finally do those upgrades and repairs which we had been putting off for so long…

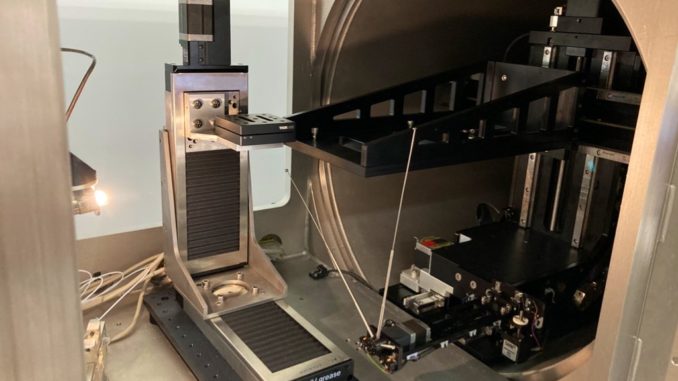

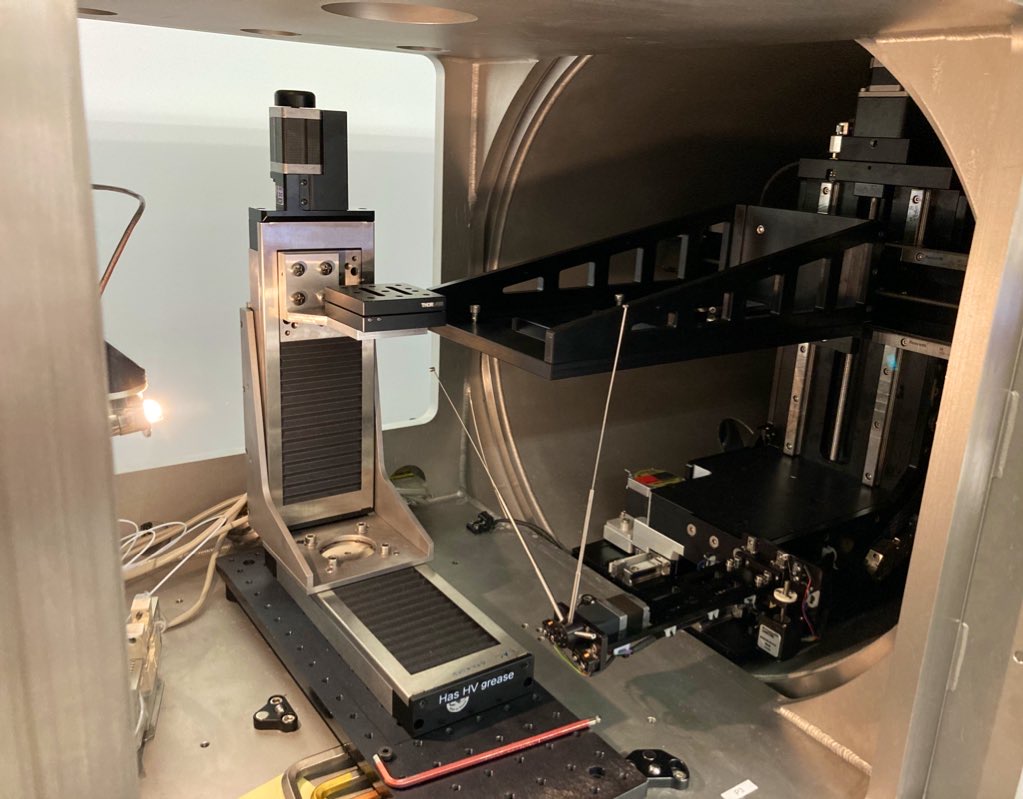

Firstly, since we need to recalibrate after detector installation anyway, this was the right time to swap over to our new sample stage. With a motion range of 150×150 mm compared to the original 100×100, we now have 225% more area we can cover. All greased up (with very expensive vacuum grease) and ready to go, we’ve mounted our new standard Thorlabs KM75 kinematic base on it to hold the new sample holders in very reproducible positions. The first sample holder has three slots with 16 positions each, for a total of 48 solid samples (alternatively, one of the slots can hold one of our flow-through cells for a mixed solid/liquid set-up. With all positions loaded and scripted, measuring a full set would take about two weeks, plenty of time for us to work on other urgent tasks.

The second upgrade was a bit of a bonus. We’ve noticed that our detector carrier didn’t come all the way forward on its rails, it would hit the limit switch ramp about 15 cm before the end. This meant that if we wanted to measure to the widest of scattering angles, we needed to move the sample stage to the downstream position to get the detector close enough for those measurements. Fortunately, we found that we could move the original limit switch ramp by another 15 cm, using the full rails, and now we can move the detector almost-but-not-quite touching the samples in their standard position. This means we can now measure the widest of angles for all samples by default. No more manual moving things around (manual means it hardly ever gets done because we are inherently lazy creatures). As a bonus, the detector carrier is now easier to reach which will help with the reinstallation and potential modifications.

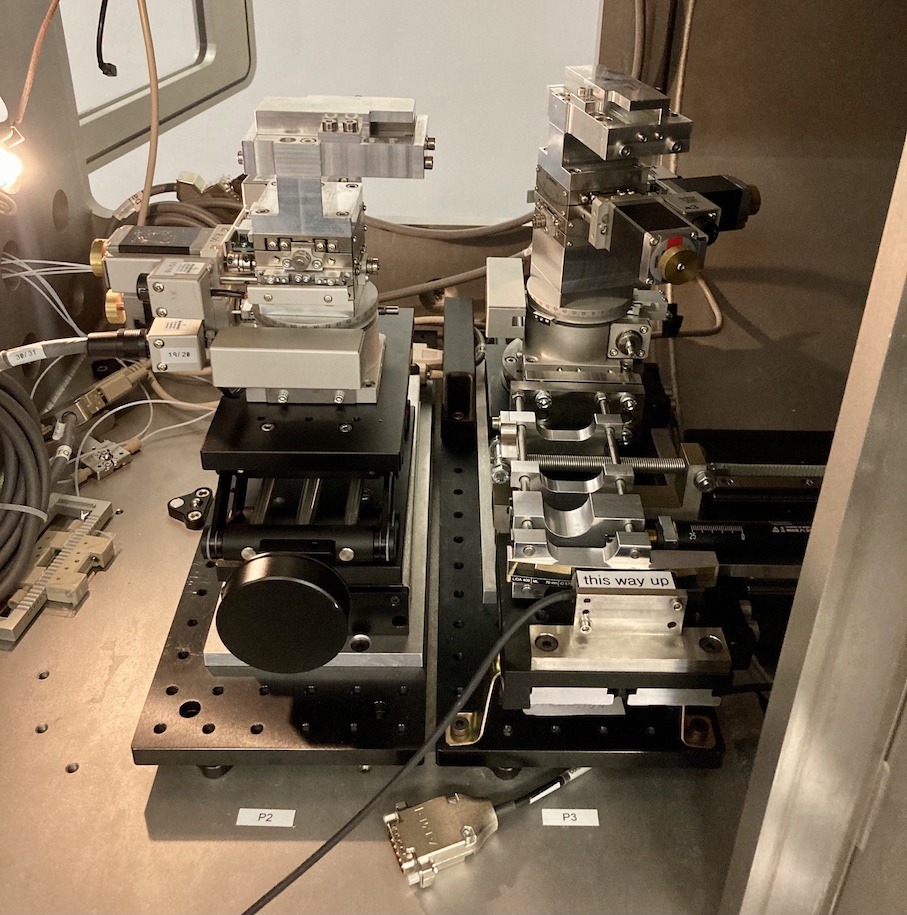

Now, you might have heard that the paper on our USAXS plug-in module has been published! It has only been tested on the synchrotron so far, but with minor modifications it should in principle fit into the MOUSE as well. So I have been rearranging bits and pieces over the last two weeks to fit this bit in, and to try and wire up all the necessary motors. So far, I am at five motors which covers all the necessary USAXS motors, but I need to increase this to seven to comfortably move the sample stage as well. That will take some more rewiring, soldering of adapter cables and rejigging, but I think we can do it. Stay tuned for this…

Then there’s the hot stage. There have been users who wanted to heat samples in situ, while connecting it to an outside atmosphere. Normally you would use a capillary for this, but these samples are highly absorbing. If we use small enough capillaries (0.2 mm), we would not be able to avoid annoying issues with the beam and necessary corrections. So we’ve developed a cell that takes flat sample carriers and sandwiches them in a heated holder. If my tests are correct, we should be able to mount samples of 0.2 mm thickness in here, and still be able to shoot through them with a 0.5 mm beam, whilst flowing gas through the samples. Heating tests have been done, and vacuum tests will follow shortly. Achievable heating rates with this cell should be about 1 degree per second thanks to its oversized heating cartridge.

Lastly, there’s EPICS. For a while now, we have been hoping to gradually transition away from SPEC towards a more modular and future-proof solution such as EPICS. This is not an easy transition, all the hardware components which underpin the instrument need to be individually integrated in a new control system. Fortunately, due to the design decisions in the MOUSE, all the hardware is connected via an internal network. It so turns out that we can have an EPICS server running on the same network to drive pieces of hardware, and that we can control these devices in the transition by sending commands to the EPICS server through our normal SPEC scripts. This means that we can carefully migrate each component one at a time to EPICS without disrupting the measurements too much. With the help of friends at Diamond, we’ve so far managed to get several pieces integrated in EPICS already, although the largest work remains getting the Eiger detector and the motor controllers integrated. The keystone is in place, however.

So, despite not having a detector, there has been much movement on the instrument front. Hopefully this will provide much better measurements in the near future for you!

Leave a Reply