[ED: I’ve started asking around for guest contributions for the LookingAtNothing site, in order to provide a broader view of the SAS-related activities that I could ever hope to achieve by myself. Our first guest to talk about his work is Dr. Grégory Stoclet of UMET at the Université Lille 1.]

PLA is a new biodegradable polymer used for in many applications such as disposable packaging as medical implants. While it behaves like a brittle material at room temperature, it quickly becomes ductile by raising the temperature a few degrees. To understand why this happens, we are studying the plastic deformation mechanisms using SAXS.

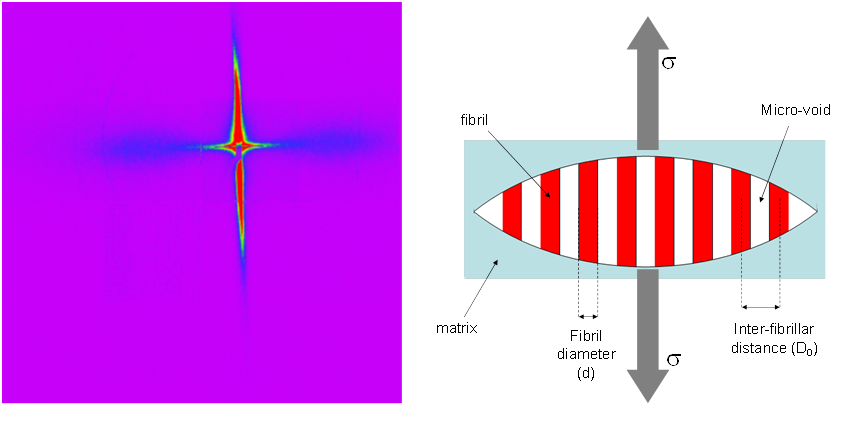

Our experiments show that a crazing phenomenon is the likely cause for the fragility [1]. This deformation mechanism, common to polymers, is an intrinsically damaging mechanism that explains the brittle behaviour of PLA. Crazes are particular structures consisting in cavities perpendicular to the stretching direction bridged by polymer fibrils that give quite nice SAXS patterns (see Figure 1).

The patterns show two features: a very intense vertical streak, and a diffuse horizontal streak. The very intense vertical streak arises from the contour of the craze. The diffuse horizontal scattering comes from the self-assembled fibrils which ensure the cohesion of the craze.

Our experiments were carried out in-situ on the SWING beamline at the synchrotron SOLEIL in France, using a homemade stretching device. Thanks to the short acquisition time (needed to observe defect formation at the required strain rates) it was possible to monitor, for the first time, the craze growth in real time (see Video 1). The video corresponds to a 5 seconds long experiment corresponding to a total deformation of the sample of 5% (recorded at a rate of 5ms/frame + 45ms of dead time).

http://www.youtube.com/watch?v=y2SIEEGoZ80

(if the video does not show, click here to open it in a separate window)

This example, recorded at low temperature, allowed to confirm results from earlier work indicating that fibrils have a constant diameter during the craze growth. In addition it reveals that crazes starts to growth at low stress before the yield point, which is generally considered as the point at which plastic deformation starts.

Practically this indicates that even for small strains, some damages can be induced into objects made into PLA, what may strongly limit the application field of PLA. For example the initial aim of substituting PET by PLA for the fabrication of bottles will probably remain a dream.

Let’s now have a look at the moment the material deforms at elevated temperatures. In this case the story is a bit more complex, as you can see on the second video below. At the end of drawing one get SAXS patterns similar to the aforementioned patterns, indicating the presence of crazes. The beginning of the deformation is, however, unusual in the sense that it begins with the apparition of very intense streaks tilted with regards to the draw direction.

(if the video does not show, click here to open it in a separate window)

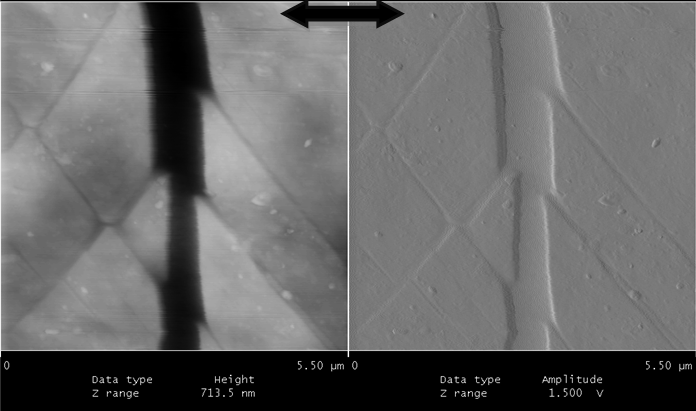

Such behaviour has never been reported before and in this case, SAXS results alone were not able to tell us what was happening. Complementary microscopy analyses have therefore been carried out. An illustration of the strain-induced nanostructure is given in Figure 2.

Without going deeply into details, the observations indicate that these streaks correspond to inclined voids, which are bridged by fibrils similar to standard crazes. This particular behaviour arises from the interaction between two elementary plastic deformation mechanisms well known in the case of polymers to know crazing and shear banding that leads to a new object we called “crazed shear bands”.

To my knowledge only in-situ SAXS experiments were able to elucidate what happens in this case, which demonstrates the power of the technique. Finally the outlook now is to find a solution to inhibit the formation of crazes into PLA. Consequently still many funny SAXS experiments to perform and I hope a new story to tell you in a near future.

About the author:

First of all I would like to thank Brian for giving me the opportunity of writing a post in his blog. To briefly introduce myself, I’m an associate professor working in a French lab focused on materials science. Personally, I work in the polymer physics field and my main topic of interest is the structure-property relationships of polymers. In this way I widely use WAXS and SAXS for the structural characterization of my polymers, especially under mechanical solicitations. Nevertheless I also work with other researchers for which SAXS can bring information, which brings me to work on catalysts, block copolymers or liquid crystals for example.

Lab page: http://umet.univ-lille1.fr/detailscomplets.php?id=39&lang=en

Web site (under construction) : http://gregfablab.wix.com/gregmsmc

Leave a Reply