After 2 years of cajoling, we now have my dream instrument: the “Multi-scale Analyser for Ultrafine Structures”, or MAUS for short. Let me introduce this beast in detail…

[Brief notes:

1. we have a position open for a permanent scientist in our group, working on data science for SAXS: programming, data analysis, etc.. The job opening (in German) can be found here: https://www.bam.de/Content/DE/Stellenausschreibungen/stellenausschreibung-002-18-605.html

2. If you haven’t done so already, please grab a free copy of our latest recommended data correction sequence publication here. It is my hope that we can move forward to test and standardize this as Universal Good SAXS Practice in the future].

I’ve been planning to build the MAUS ever since I started in Japan. Over the years, the ideas and knowledge gained from looking at other instruments were combined, and put in various instrument building proposals. After starting at BAM, this proposal was accepted. However, given the strings attached, and following the recommendations from the readers of this blog, it was decided not to build this myself, but to let the instrument be built. All the ideas were put in a highly detailed request for quotations, and the proposal received from the French manufacturer Xenocs was chosen, allowing them to build our custom-designed instrument.

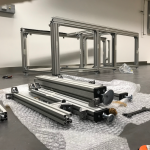

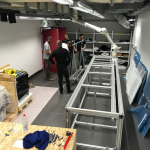

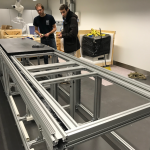

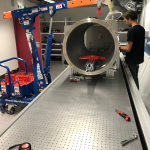

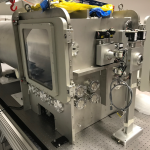

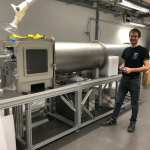

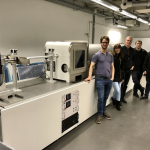

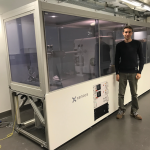

Fast forward to November 2017, after a few meetings hammering out the engineering details, the instrument was being delivered to a newly renovated building on our main campus (this year, also our offices should move there). The instrument is now constructed, and is in its commissioning phase, where we are trying to find out exactly how best to operate it.

In a few months, once we’re confident with the way it runs, a segment of MAUS time will be made available to outside collaborators (similar to a user facility). For this, brief mini-proposals will be solicited, and our future instrument responsible will then select and schedule the various experiments. our future instrument responsible will then guide the user in setting up, running and interpreting their results in the framework of their research, with the expectation of a co-authorship on resulting papers.

The big benefit of our instrument compared to synchrotrons is time: we have longer time-slots available, allowing you to do proof-of-principle measurements, long-duration in-situ experiments (up to a week), and letting you to return regularly with optimized and fine-tuned experiments. We also have more time available for in-depth collaboration on the various research topics.

At the same time, we’ll be using the instrument ourselves to further work on our own projects and collaborations, in particular in fine-tuning of the SAXS measurement methodologies, and pushing the limits of the technique and the instrument.

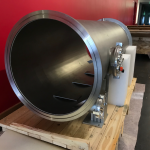

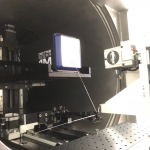

The instrument itself is quite unique, combining several nice features. It has two microfocus X-ray sources on a motorized stage (allowing automatic switching), one with a copper, and one with a molybdenum anode (emitting 8 and 17 keV photons, respectively), with parallelization optics. The collimation section has three sets of scatterless slits, leading to a nice clean beam. Then we have an enormous sample chamber, with an internal space of 500x500x600 mm, an on-axis alignment microscope, and various sample stages (including a miniature hexapod for grazing incidence work). The detector is an in-vacuum Eiger 1M on a three-axis stage. This lets us move it to any desired position with respect to the beam and sample, with sample-to-detector distances of mere centimetres to 2.5m.

The whole thing is controlled using SPEC, with some convenience macros and interfaces provided by SAXSLab (which was bought by Xenocs not too long ago). That means that anyone with some synchrotron experience will not have long to learn before they can operate the instrument, and vice versa, once someone knows how to operate this instrument, going to synchrotrons will not be hard either. It can even be remote controlled, provided you load it up with sufficient sample.

The enormous vacuum tube and sample chamber does require a while to pump down, it takes about six minutes to reach 1 mbar of pressure. Venting it takes about 1.5 minutes. Rather than doing many quick sample changes, it is rather recommended to load up large plates of samples at a time.

The data we get out of it will be stored in the NeXus format (work in progress), allowing us to continue with the Diamond team on extending DAWN for laboratory use, and improving DAWN’s data correction procedures. We have already been working on this in 2017, as Xenocs was able to rent us one of their vertical NanoInXiders for a while to help us prepare for the MAUS.

So, as you can probably sense, I’m very chuffed with this new instrument. I am working hard to find sufficient time to make it work the way I’ve always dreamed it would!

Do check out the pictures of the installation and the instrument below:

Hi Brian,

do you think that this set up could benefit from a smaller pixel detector with no dead-time between the images?

With warm regards,

Vlad

Hi Vlad,

We are a bit limited by the beam dimensions at this point, so smaller pixels might not get us much further. However, two energy thresholds (so that we can make a bandwidth filter, to filter out high-energy cosmic rays) would be good. Also, a thinner, more absorbing active layer would improve the signal at higher angles of incidence. Also, an even higher linear dynamic range would be (as always) welcomed by the synchrotron people :).

Dear Vlad,

Please check out the latest blog post here to find my opinions on what we would need for SAXS:

http://www.lookingatnothing.com/index.php/archives/2630

Cheers,

Brian.