Over the last half year (damn 2022 goes fast!) I haven’t spent so much time on the USAXS project (see our last publication from 2021 on that topic here) . Nevertheless, there are some interesting things coming up that could be cool if they work. So here’s a quick summary of what I’ve been up to on that front…

Motor controllers

One of my gripes in the past was that I had to use thick, self-soldered cables inside the vacuum chamber that were very bulky. The reason behind this is that the vacuum feedthroughs we use for our 15-pin sub-D connectors actually mirror the connections, so that pin 8 on one side is connected to pin 1 on the other, 7 to 2, 6 to 3, etc. That understandibly doesn’t work well, so I had soldered mirrored 15-lead motor cables that alleviated that problem but led to the bulky thick cables.

Meanwhile, I assembled a second 12-axis motor controller, and here I mirrored all my soldered connections. When I tested this with my mirrored cables, it works just fine, so I thought I was all set. It looked pretty good too:

Done. Nothing seems shorted or on fire. Soldering is terrible in places though due to lack of access when soldering. Version 3 will be easier in that respect. pic.twitter.com/gSfOd2bIGC

— Brian R. Pauw Ⓥ (@drheaddamage) April 8, 2022

However, when I then tested this on the MOUSE with the actual vacuum feedthroughs, I again got intermittent problems, so obviously I mucked up somewhere. This confuses me greatly, but I’ll figure it out eventually with more testing. For the time being, however, that means we’re back to bulky cables, unfortunately.

A fast stage for syncrotron scans

One issue when using this at the synchrotron was the slow speed of the step scans. We figured we could speed this up by implementing flyscanning, where the linear stepper motor is driven in a continuous profile, and we read out the encoder strip and PIN diode as it scans. This should bring the measurement times down considerably, by our estimates to only a few minutes.

A few minutes in synchrotron life is still pretty long though. So I’ve been playing around with the idea of using one of those fast-but-precise magnetic drives for actuation. That took some redesigning, but as of this week, I’ve finally had the necessary components in place for a test. That test shows that my idea worked: we can drive this rotation in a fast and precise manner, with, if my estimation of minimal flexing of the system holds, should translate to at least rotations of several tens of nanoradian.

Lab time again, testing the movement of the new quick mag-drive driven USAXS rotation stage. Reproducible movement of the arm end (310 mm from the rotation center) of 10 nm! That works out to rotations of… 32 nanoradian, that is 1.8 micro-degrees. pic.twitter.com/mTPFdD6OTI

— Brian R. Pauw Ⓥ (@drheaddamage) June 8, 2022

Put this in context to the approximately 7 microradian Darwin width of the Si(220) crystals, and you can see that we’re well north of the rotation precision required for these. As for speed, this thing can move at truly scary speeds, so I don’t think we have any concerns there either. Now we just need to get this to follow a sigmoidal speed profile to put the cherry on the cake, but that’s “just” a programming issue:

Ps. Fast movement, for now 100mm/s with an acceleration of 5m/(ss) is plenty quick enough. pic.twitter.com/XQY4spfcxQ

— Brian R. Pauw Ⓥ (@drheaddamage) June 8, 2022

Redesign of the upper segment

The upper segment of the USAXS towers are also a bit too bulky for my taste, as they include motorized rocking stages that – in the end – proved unnecessary. Manual rocking stages would do just fine for the angular ranges we’re scanning in. So I will simplify that, but that means calculating a new spacer height to keep the crystal at the right height, and I’ve not put myself in front of those drawings for a while. This’ll be done at some stage

MOUSE X-ray source issues

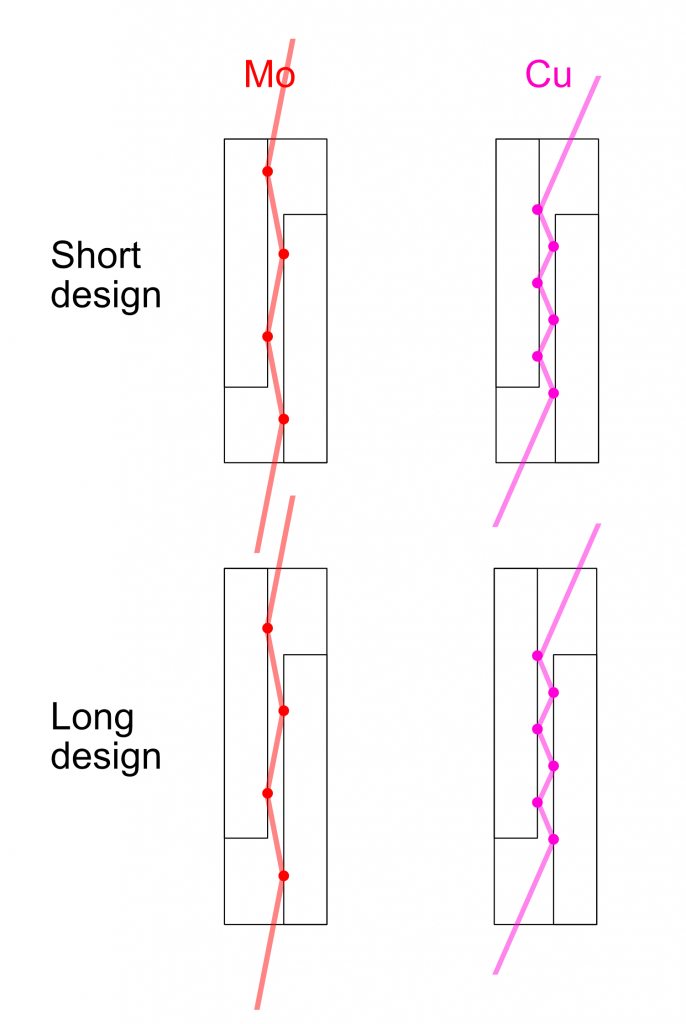

Previously, we’ve used the MOUSE molybdenum X-ray source for the USAXS, which isn’t ideal as it isn’t too bright, and the detector is only 50% sensitive to its photons. The crystals we designed way back when were designed for this energy, though, and so we stuck with that. The higher energy was also a boon at the synchrotron, with fewer headaches regarding air scattering and absorption playing a role.

Recently, however, the high-voltage power supply for our molybdenum source failed, and supply-chain issues meant we couldn’t get a replacement quickly (we just installed a temporary replacement component yesterday). So I’ve been looking into alternatives for the USAXS crystals. Having new, shorter crystals cut for our copper source would allow us to work with the much brighter source in the MOUSE. New crystals, however, are expensive, and I suspect I’ll need to show justification and output before I ask for more expensive bits for this dragged-on project.

There is another interesting option, though. I did some calculations yesterday, and it looks like I can actually get *six* copper “bounces” through our original crystals (see Figure 1). While this probably won’t improve the rocking curves much, it would mean that we can benefit from our 100x brighter Cu-source for USAXS experiment, even if we lose another 20% due to the extra bounces. In a few weeks, when the MOUSE has chewed through its current batch of samples, I’ll start experimenting and seeing if that’ll work. I don’t know about you, but I find this an exciting option!

So stay tuned for upcoming experiments!

Leave a Reply