This news has also been covered by Birmingham University, Martin Hollamby and The Schnepp Group, and may appear in other news outlets soon. [update: like at azonano.com, nanowerk.com, the Mumbai mirror, FuelCellsWorks, supergen fuel cells, green car congress and phys.org. update2: Some more selected outlets: Ars Technica, the Conversation, World of Chemicals, Renewables Europe, Hydrogen and Fuel Cell letter (paywalled), and The Himalayan Mirror ]

Imagine you could turn pigs into catalysts. You’d think that that would take quite some work, but it turns out to be surprisingly easy as long as you have a good oven and some salts lying around. This has been demonstrated by Zoe Schnepp (of the newly formed Schnepp Group at the U. of Birmingham) in collaboration with Yuanjian Zhang, Martin Hollamby and others during her time here at NIMS, and has just been published here. So what did we do?…

Her work involves doing chemistry with readily available materials, and her office therefore used to be home to bags of rice husks, seaweed and oodles of gelatine. Besides that, she focused on doing the chemistry as easily as possible, which mostly consisted of mixing items and chucking it into a high-temperature oven. The easy availability of her source materials and the simplicity of the syntheses meant that we could work with large amounts of samples. In the case of SAXS, this is extremely valuable as we require cubic millimeters of material (and a bit more for those like me with shaky hands).

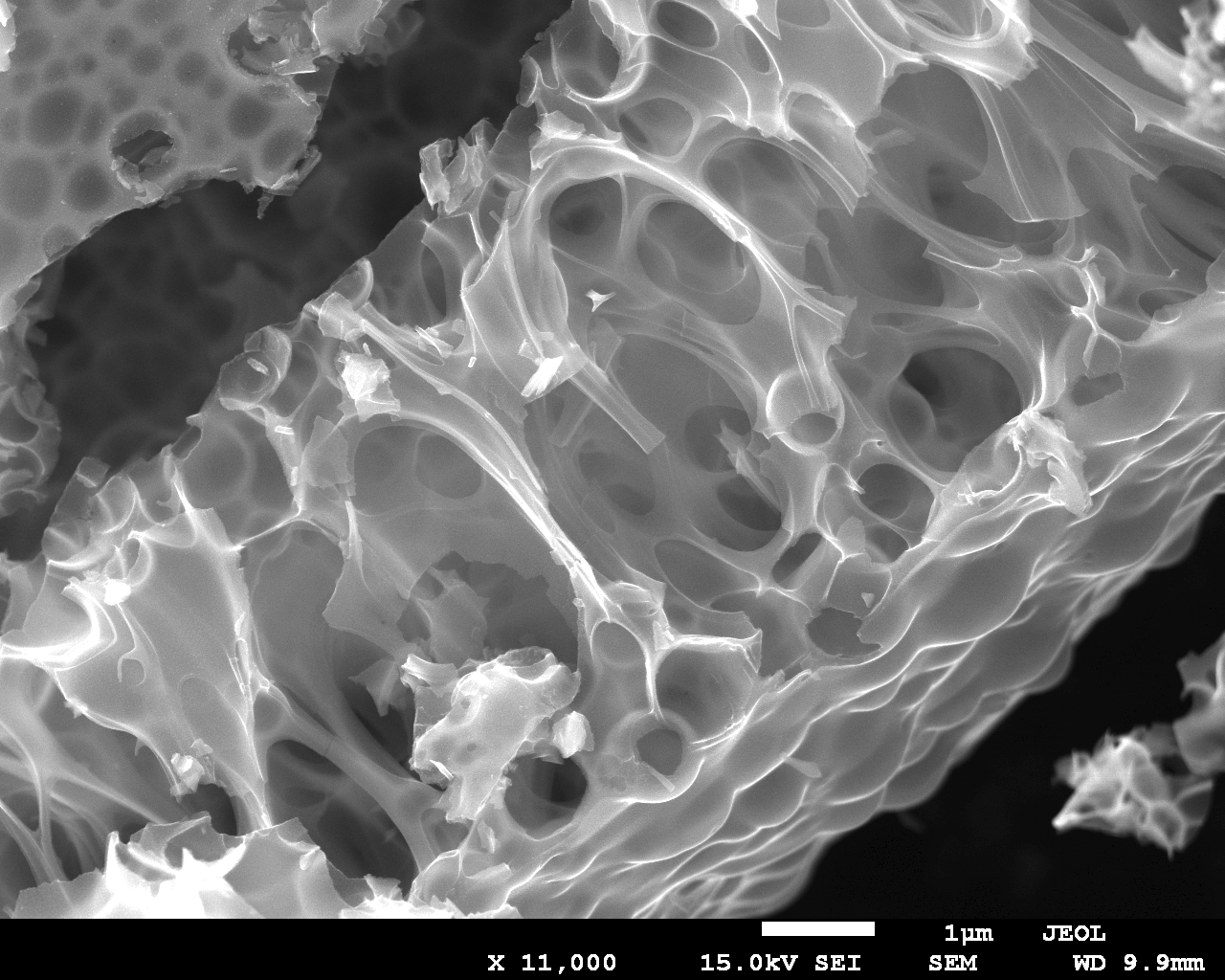

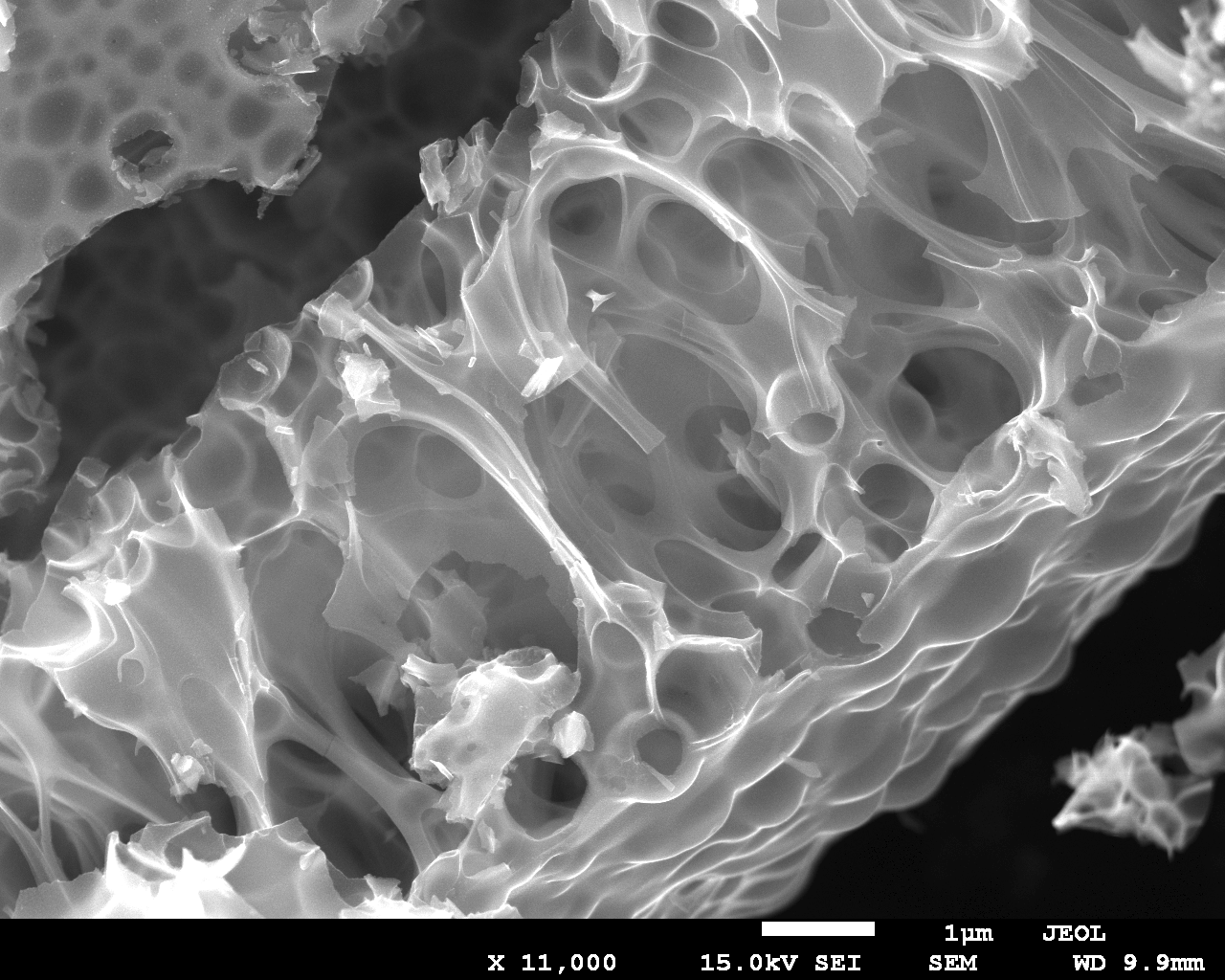

Without going into too much detail about the things I know little about, the SAXS aspect of the research turned out rather well. In collaboration with Martin Hollamby, we determined the size distributions of a multi-phase material (of course after proper data corrections). The samples consisted of a carbon foam (from the carbonised gelatine), with some containing magnesium oxide and iron carbide nanoparticles, and some where the particles had been removed using a mild acid wash (the latter were the most catalytically active). So we had two types of samples, and four phases: vacuum, carbon, magnesium oxide and iron carbide. In the acid washed samples, we mostly had a two-phase system of vacuum and carbon.

With SAXS, it is normally not recommended to try to measure anything containing more than two phases, as you cannot easily distinguish between the two. We had some help here, however: TEM and electron density contrast.

The electron density contrast between magnesium and carbon is smaller than that between vacuum and carbon, so you would expect an increase in scattering signal from those entities if you remove the magnesium oxide (and replace those sites with vacuum). Conversely, the contrast between iron carbide and carbon is larger than that of vacuum and carbon, so that removal of the iron carbide particles would reduce the associated SAXS signal.

Analysing for polydispersity of our measurements (using the MC procedure after suitable data correction steps), we could see two populations of particles, a large one and a smaller one. After etching, the larger sized population reduced in scattering power, and the smaller one increased. This indicates that the larger one may be the iron carbide particles, and the smaller one the magnesium oxide. There is also scattering appearing from very small-sized structures, which probably can be ascribed to an increase in surface roughness after etching.

Fortunately, our hypotheses on the particle sizes agrees with the TEM results: larger particles are iron-containing particles, smaller ones magnesium-containing particles. This behaviour was consistent for four material compositions, and these results furthermore do not conflict with any of the other techniques applied to the materials (porosimetry, elemental analysis, etc…)! Suffice to say, we’re quite proud of this work!

Leave a Reply