We have a user coming next week who’s interested in cooling their samples as fast as possible. This rapid cooling has a drastic effect on the solidification behaviour and more closely resembles the cooling behaviour of the industrial processes. The fastest practical way to cool, we think, is to switch from a hot liquid flow to a cold liquid flow, close to the sample holder. Here’s a straightforward solution we put together.

So we have a few circulating chillers that can be filled with a range of liquids. Our star of the show is a Lauda bath that can in principle handle temperatures between -50 to 250 degrees C, but we have a few more modest ones too. Set one to a high temperature, the other to a low temperature, and make something to switch from one to the other flow rapidly. Combine that with a liquid-cooled sample holder and you’re in business.

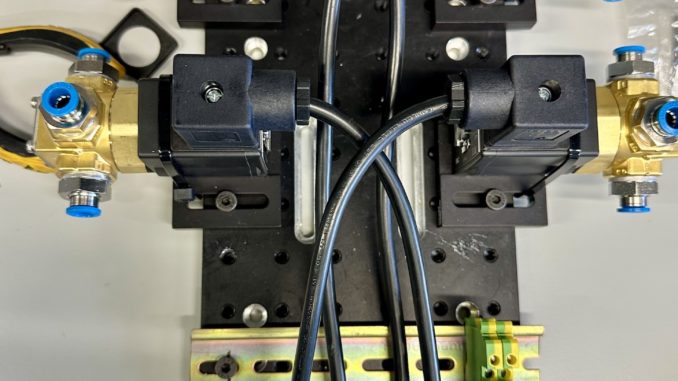

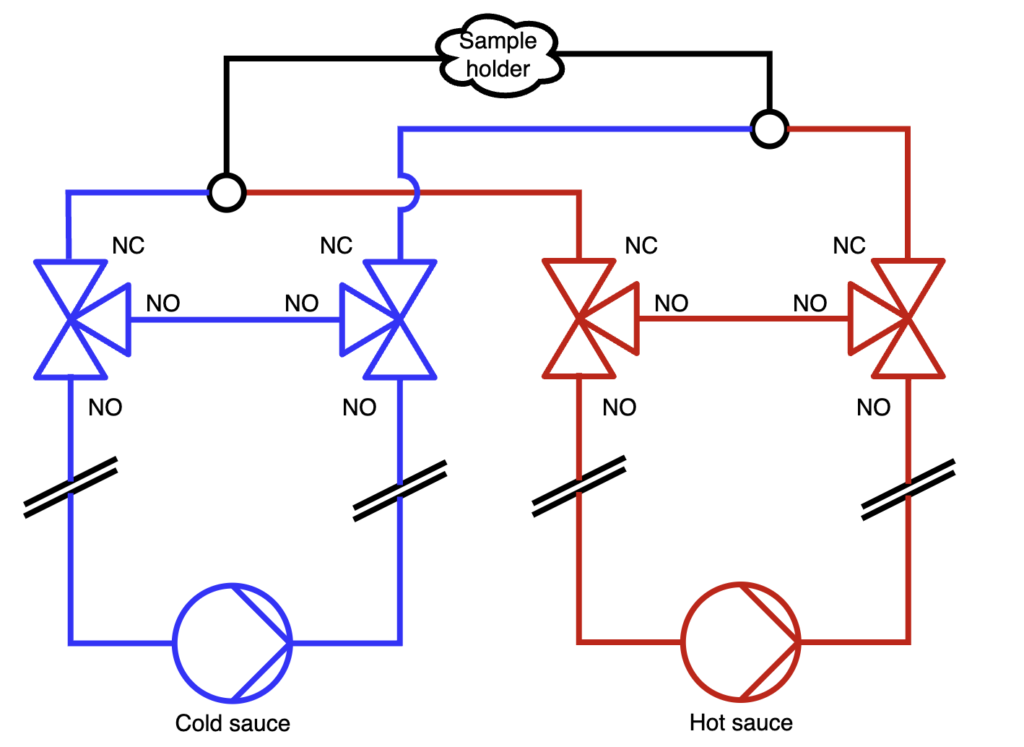

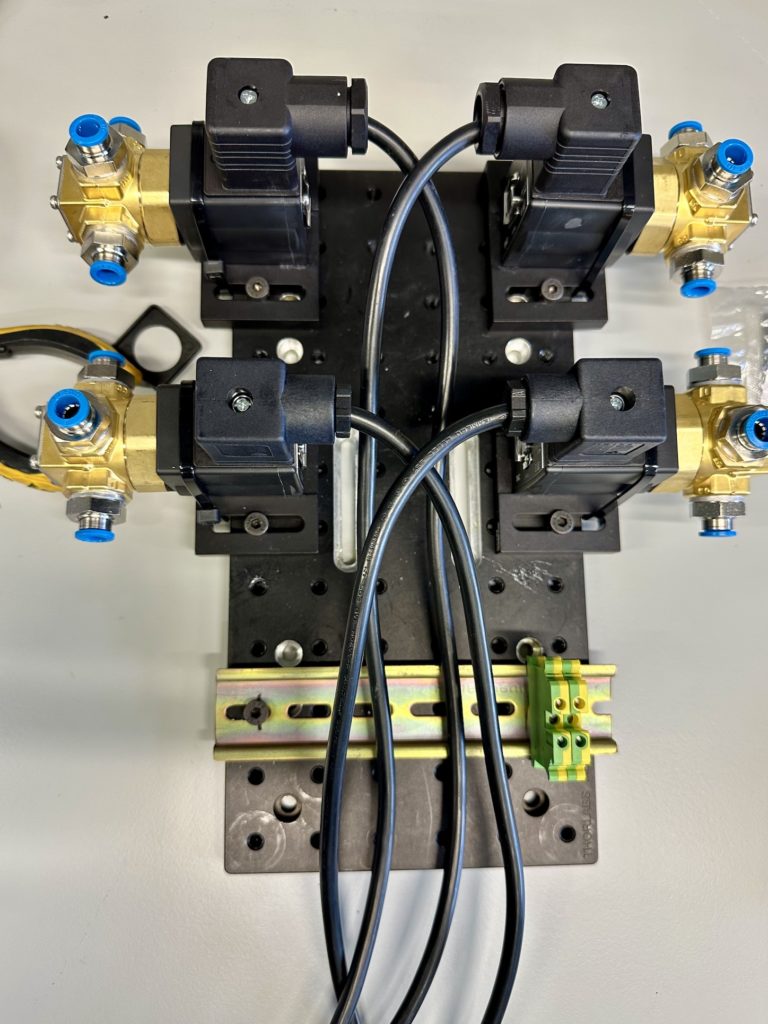

The trick we had to figure out is how best to switch from one liquid flow to the other. Normally, this is not a difficult task, but we need to do it in such a way that we don’t interrupt either flow. If we use normal two-way valves, we would block either one or the other flow during the experiment, which can be damaging to the pumps. So we came up with a way to switch using four solenoid valves and two T-pieces.

Secondly, we needed electronics that ensured it was either in the one or the other position. The easiest solution is to use a relay, and I happened to have a spare DIN-rail mountable 24V relay from our safety interlock project around. With the help of a new lab technician, we put the parts together to find that we actually have three states of the system:

- completely unpowered: both loops are in bypass, all solenoids closed. No liquid going to the sample cell.

- With power to the solenoids, two of them will be switched on, and the cold side is flowing through the sample cell.

- when the relay is activated (directly fed from our Arduino Pro Portenta Machine Control box), the solenoids of the hot side is activated at the same time as those on the cold side are closed, passing that through the sample cell.

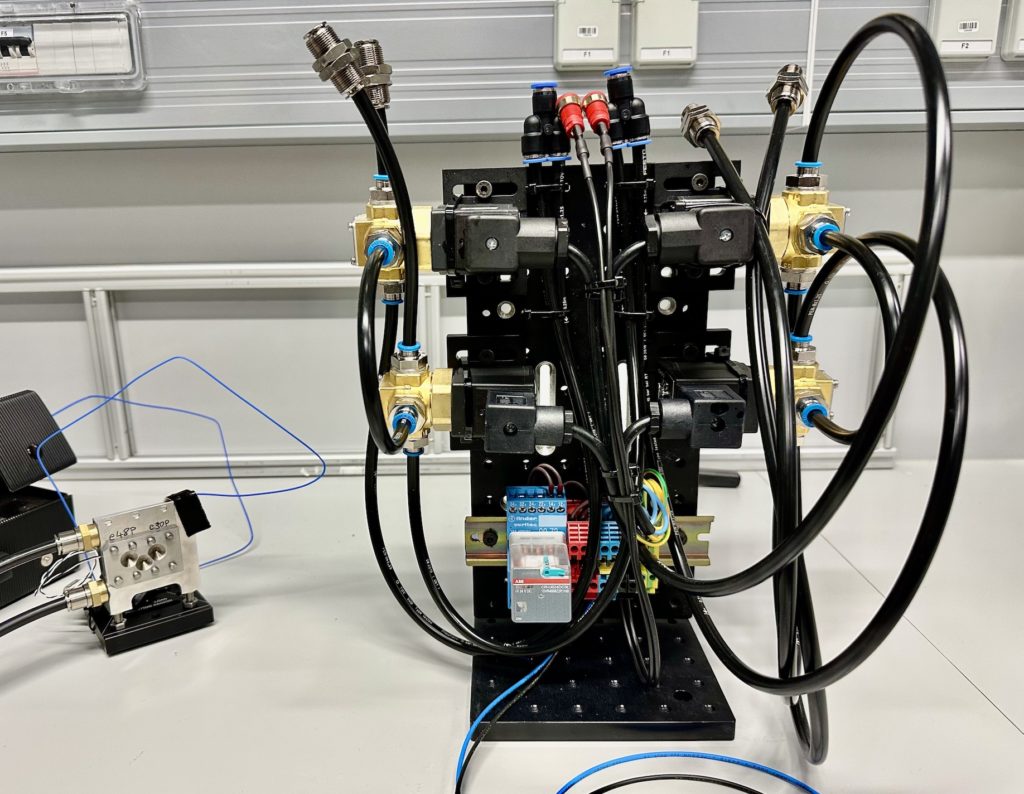

The final prototype has been tested and on the little sample holder we have, it can change the temperature by about 50 degrees in less than 30 seconds. Most of the latency seems to be in a stainless steel component of the holder. Once that has been swapped out with an aluminium version, I suspect we’ll get a bit better performance still. Lastly, if it’s really rapid cooling we want, we can swap out the cold chiller for a liquid nitrogen source and enjoy the fireworks.

Once we have some actual performance data, I will let you know how it went. Until then, this seems to be a suitable prototype that will at least last the coming experiments. If we get more experiments like this, we’ll probably design it a bit neater, put it in a box with bulkhead connections for liquids and electronic connections, and probably separate the electronics from the valves a little better. It’s all 24V, so I’m not overly concerned, but liquid switching right above electronics is just not proper. Let’s call this version 0.1 for now.