Keen readers amongst you will have followed the development of our Ultra-SAXS instrument over the years, from its initial stages as a proof-of-principle, cobbled-together device in Japan, to the proven, modular device it is now. Over two beamtimes at Diamond, we have developed the alignment procedures and expertise required to install and operate the instrument, in an interleaved USAXS/SAXS/WAXS manner. This seems to work well, so we figured it was time to summarize the result in a paper, the draft of which is now available on ArXiv… Read on for a brief review of its history:

Based on my own blog posts, the first hints started about six years ago here. That started a long development process, which involved lots of time by me in the workshop making pieces, figuring out instrument control in Python, and getting an old rotating-anode generator working again after ten years standing still. Additionally, I had to build some of my own NIM-electronics using an Arduino.

I could then do some alignment, go backward for more modifications, and finally getting some counts on the other side of my two crystals. Then back to modifying it, learning some lessons from the more experienced, and going back for a complete redesign, after the X-ray generator broke down for the last and final time.

Putting that together was a much quicker process than the first time around, mostly due to the use of many 3D printed parts. The initial scans showed promise, but didn’t quite make me happy at first. Not long after, however, we got the first measurements that actually made a little sense, and the game was on… But I had to leave Japan before I could really take version 2 any further.

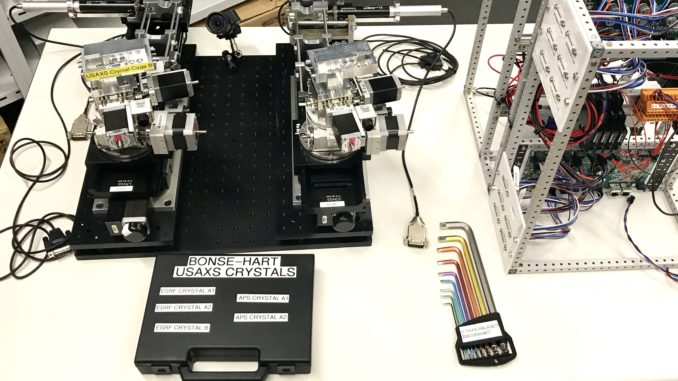

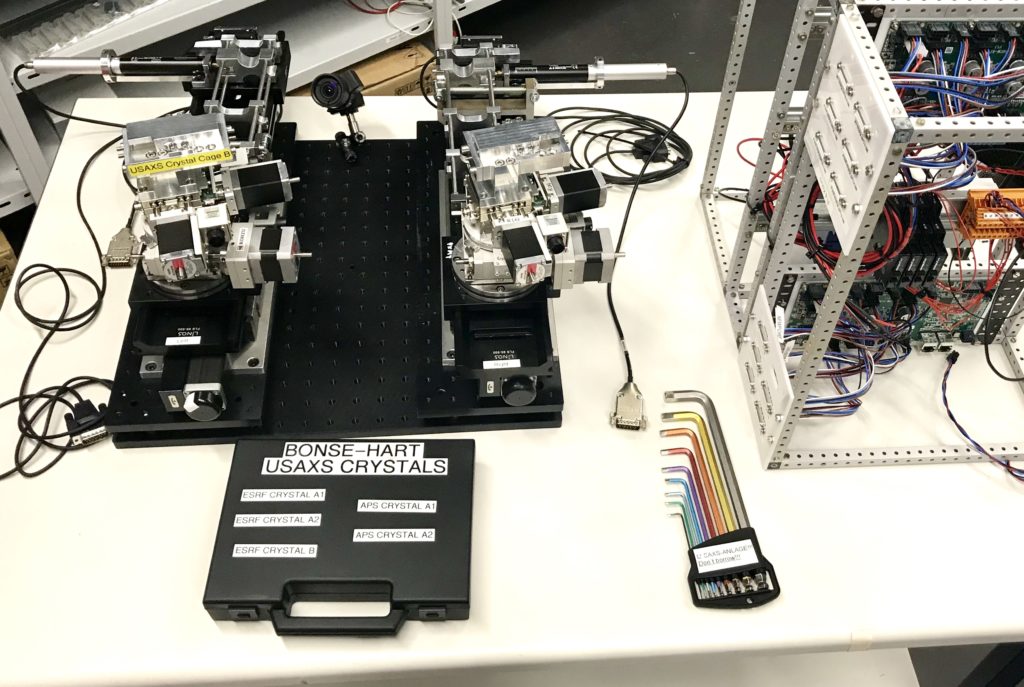

Based on the results of version 1 and 2, version 3 was a completely new redesign, intended to work at synchrotrons. This version was funded equally by BAM, Diamond and DUBBLE, with BAM’s workshop delivering many well-manufactured pieces. Seeing it work a little led to a slight rethink on some of the components,

and we enjoyed a generous amount of machine development time over two beamtimes to commission the new modules too. Which, finally, brings us to today. The manuscript detailing the instrument and its nice output is ready for review…

… we’re not done yet, though. The next step is yet another slight redesign of the instrument, so that it fits inside the MAUS as well as at Diamond, and this allows us to make several improvements *again*. Given the history, I believe that this — or indeed any — instrument development is never finished. There’s always more, better, easier, smaller, always the next hilltop to cover. It’s a long journey, but when taken in stride, it is a very enjoyable process indeed.

Leave a Reply